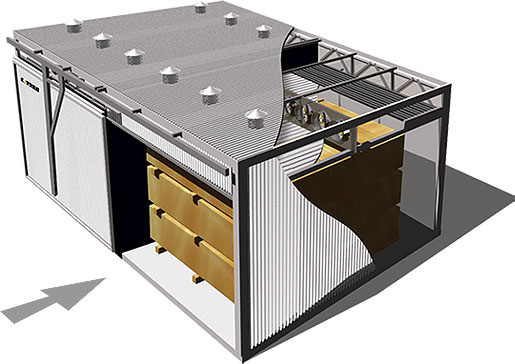

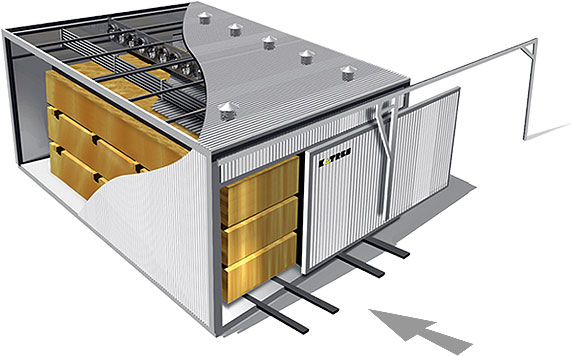

Batch Kilns

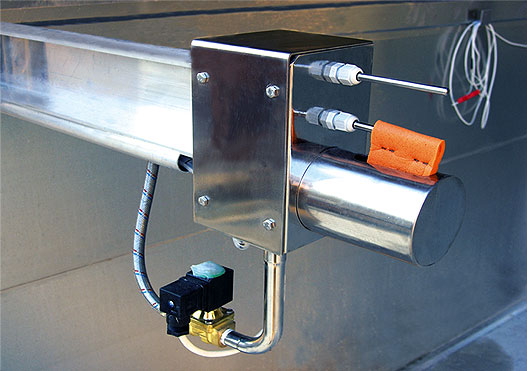

A standard Batch Kilns are one of the most commonly used types of dryers in the wood industry, and still holds a dominant position on the wood drying market. The main reason is surely the suitability for drying of all kinds of timber and thicknesses in the relatively smaller initial costs. In the basic standard designs, we offer various types of equipment that are able to ensure the maximum quality of drying.