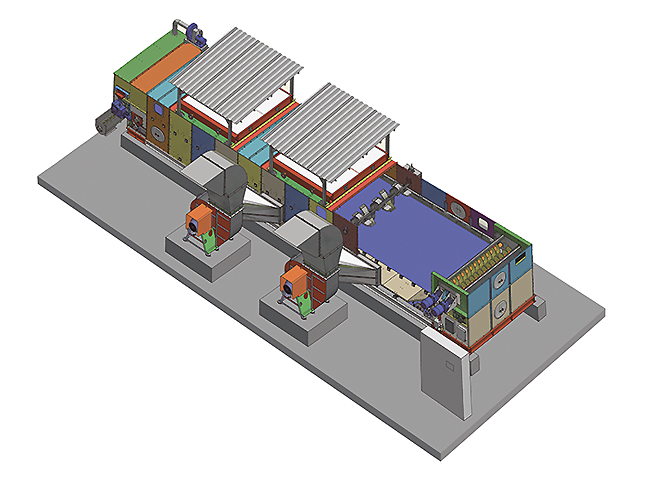

Belt Dryer for Sawdust and Woodchips – type KBD

There are many different materials that can be dried so that can be further processed and utilized. Some require specific handling in a drying process, others require tightly regulated parameters of humidity and temperature of the drying process, for others it is realistic to evaluate assuming minimal cost by using waste heat. Such drying parameters offer LOW TEMPERATURE belt dryer by KATRES.